Your trusted engineering and solution partner

Energize your automation!

Your trusted engineering and solution partner

Energize your automation!

Your Benefits

Global support

We are keen on travelling and happy to support you on-site at any edge of the world. Our engineering team is fluent in 7 languages.

Experience

18 years of international success. Just check out the list of 411 projects we have completed.

Client-oriented approach

We pay attention to the smallest details in your request to exceed your highest expectations.

Cost-efficiency

We offer the highest quality at very competitive prices due to our location.

Competency

We are a certified Solution Partner of Siemens AG and are proud of our various professional certificates.

Handshake reliability

We build a trustful relationship with our customers so that words are as strong as contracts.

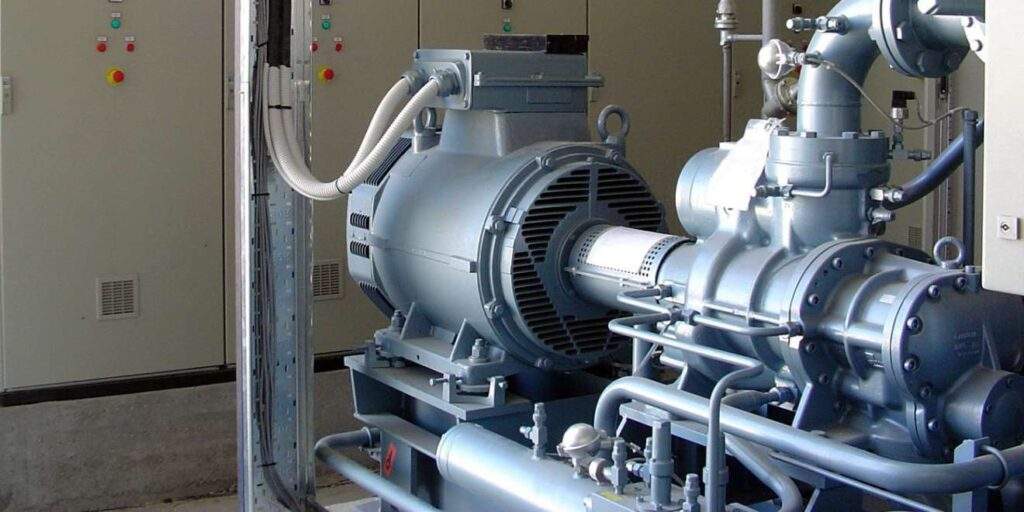

Expertise in Industries

Technologies

News

-

CEB Kerawalapitiya, in Colombo, Sri Lanka

We have started the commissioning phase of the project CEB Kerawalapitiya, in Colombo, Sri Lanka.

-

New website

Our company has a new website now. We hope you like it. Your feedback is welcome.

-

Siemens Energy Germany

We have signed a framework contract with Siemens Energy Germany for worldwide projects.